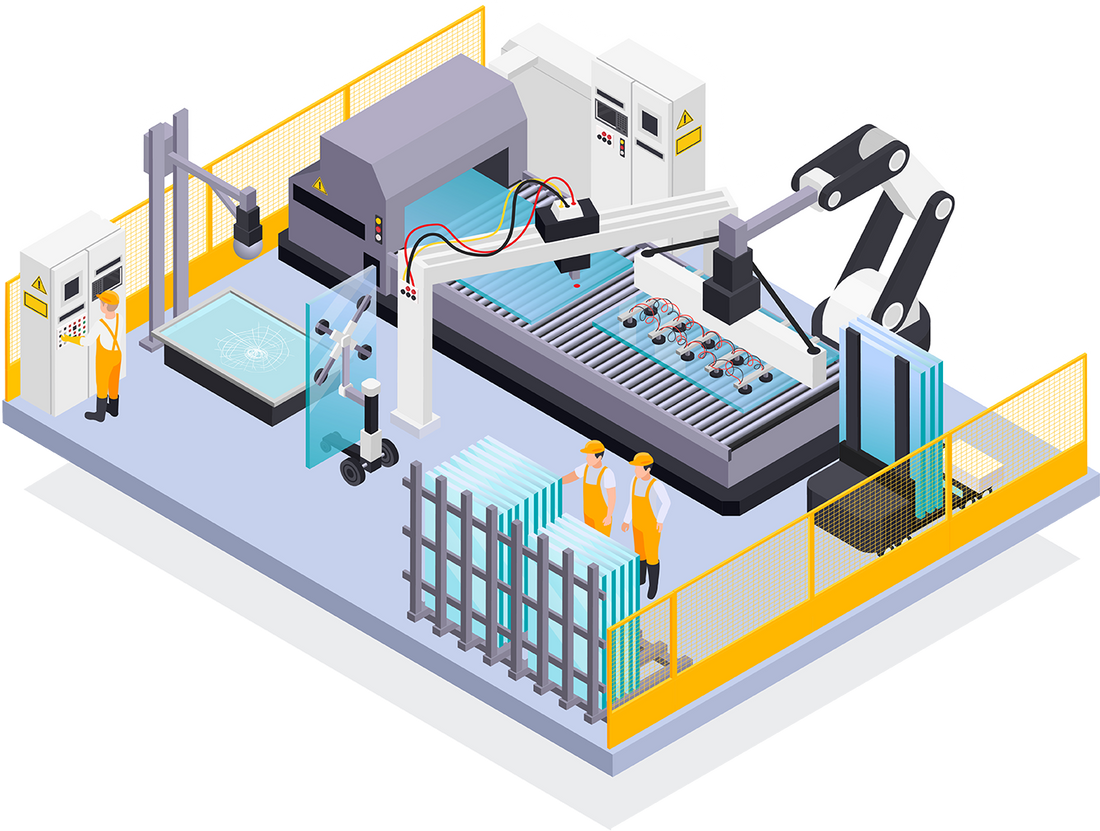

In the rapidly advancing world of automation, precision and reliability are paramount. Each component within a control system must function flawlessly to ensure the smooth operation of the entire manufacturing process. This is where custom plastic fabrication, particularly the processes of "cut to size" and "CNC routering," come into play. By tailoring components to meet specific needs, we can enhance the efficiency and reliability of automated systems.

The Importance of Precision in Automation

Automation relies on the seamless integration of numerous parts. When these parts work in perfect sync, manufacturing efficiency can increase tenfold, reducing overall costs and enhancing productivity. However, the failure of even a single part can lead to production delays and expensive repairs. This makes precision an essential factor in the fabrication of components for automation.

Precision in automation is not just about exact measurements. It’s about ensuring that each component, no matter how small, performs its function perfectly within the larger system. A minor error in one part can disrupt the entire process, leading to significant downtime and increased costs. Therefore, achieving high precision in the fabrication of these parts is critical.

Custom Plastic Solutions: The Key to Reliable Automation

Bramur specializes in providing custom plastic solutions designed specifically for automatic control systems and equipment. Our expertise in plastic fabrication allows us to create components that are tailored precisely to your specifications, ensuring optimal performance and longevity.

Plastic materials are particularly advantageous in automation for several reasons. They are lightweight, durable, and resistant to corrosion, making them ideal for a wide range of applications. Additionally, plastics can be molded into complex shapes that would be difficult or impossible to achieve with other materials. This flexibility allows for the creation of highly specialized components that are perfectly suited to their intended use.

Cut to Size: Perfect Fit, Every Time

One of the critical aspects of our plastic fabrication process is the "cut to size" service. This ensures that each component fits perfectly within the system it is designed for. By cutting plastic to precise dimensions, we eliminate the need for additional adjustments or modifications, saving time and reducing the risk of errors.

The cut to size process involves more than just slicing material to specified dimensions. It requires a deep understanding of the material properties and the application requirements. At Bramur, we use advanced cutting techniques and equipment to ensure that each piece is crafted with the utmost precision. This level of accuracy is crucial for maintaining the integrity and performance of the entire system.

In addition to improving fit and function, our cut to size service also helps to minimize material waste. By optimizing the use of raw materials, we can reduce costs and contribute to more sustainable manufacturing practices. This is increasingly important in today’s environmentally conscious market, where efficiency and sustainability go hand in hand.

CNC Routering: Precision and Efficiency

CNC routering is another cornerstone of our fabrication process. This advanced technique allows us to create complex shapes and intricate designs with unparalleled accuracy. Using computer-controlled routers, we can achieve a level of precision that is essential for the intricate components used in modern automation systems. CNC routering not only enhances the quality of the finished product but also speeds up the production process, allowing for faster turnaround times.

CNC routering stands for Computer Numerical Control routering, a process where a computer controls the movement of the cutting tool. This allows for highly precise and repeatable cuts, making it possible to produce complex geometries and detailed features that would be difficult to achieve manually. The use of CNC technology also ensures consistency across multiple parts, which is essential for large-scale production runs.

The efficiency of CNC routering extends beyond just the cutting process. The digital nature of the system means that design changes can be implemented quickly and easily. This flexibility is invaluable in a fast-paced manufacturing environment, where the ability to adapt to new requirements or address issues swiftly can provide a significant competitive advantage.

Applications of Custom Plastic Components

Our custom plastic components are utilized in a wide range of applications, from simple conveyor belts to advanced robotics. The versatility of plastic, combined with our cutting-edge fabrication techniques, makes it an ideal material for various automated systems. Whether you need components for industrial machinery, medical devices, or consumer electronics, our custom solutions can meet your needs.

Industrial Machinery

In industrial settings, the reliability and durability of components are crucial. Custom plastic parts are used in machinery for functions such as guiding, supporting, and protecting other components. The cut to size and CNC routering processes ensure that these parts fit perfectly and perform reliably under demanding conditions.

Medical Devices

In the medical field, precision and hygiene are paramount. Custom plastic fabrication allows for the creation of parts that meet stringent medical standards. Our cut to size services ensure a perfect fit, while CNC routering provides the precision necessary for complex medical devices.

Consumer Electronics

Consumer electronics often require small, intricate components that fit together precisely. Our custom plastic solutions provide the accuracy and consistency needed for these applications. The use of CNC routering allows for the creation of detailed features that enhance the functionality and aesthetic appeal of electronic devices.

The Benefits of Custom Plastic Fabrication

Custom plastic fabrication offers several key benefits that make it an ideal choice for automation systems:

- Precision: Advanced techniques such as cut to size and CNC routering ensure high levels of accuracy, reducing the risk of errors and improving system performance.

- Durability: Plastics are resistant to wear, corrosion, and impact, making them ideal for demanding applications.

- Flexibility: The ability to mold plastics into complex shapes allows for the creation of highly specialized components.

- Efficiency: Custom fabrication processes minimize material waste and reduce production times, leading to cost savings.

- Consistency: CNC technology ensures that each part is produced to the same exacting standards, providing reliability and consistency across production runs.

Why Choose Bramur?

Choosing Bramur for your plastic fabrication needs means opting for quality, precision, and reliability. Our custom plastic solutions, cut to size services, and CNC routering capabilities set us apart from the competition. We are committed to delivering products that meet the highest standards of performance and durability.

Our team of experts works closely with clients to understand their specific needs and develop solutions that meet their requirements. We use state-of-the-art equipment and techniques to ensure that each component is manufactured to the highest standards. Whether you need a single prototype or a large production run, we have the capabilities to deliver.

In addition to our technical expertise, we pride ourselves on our customer service. We believe in building long-term relationships with our clients based on trust and mutual success. From initial consultation to final delivery, we are dedicated to providing the best possible service and support.

Conclusion

In the world of automation, the smallest component can make the biggest difference. Ensuring that each part is fabricated with precision and tailored to fit perfectly within the system is crucial for maintaining efficiency and minimizing downtime. At Bramur, we are dedicated to providing custom plastic solutions that meet these exacting standards. With our expertise in cut to size services and CNC routering, we are revolutionizing the way components are manufactured for automated systems.

Explore our range of services today and discover how we can help you achieve greater efficiency and reliability in your automation processes. Contact Bramur for all your custom plastic fabrication needs and take the first step towards enhancing your manufacturing capabilities.